We've been working on this project for a long time and it's very exciting for us to finally be launching our online shopping cart. You will find here all of the main toner and ink cartridges that are on the market: Brother, Canon, Epson, HP, Lexmark, Xerox and Samsung. We offer only original (OEM) products, at very low prices. We invite you to shop around for your cartridges; we are confident we're offering the best deal.

We've been working on this project for a long time and it's very exciting for us to finally be launching our online shopping cart. You will find here all of the main toner and ink cartridges that are on the market: Brother, Canon, Epson, HP, Lexmark, Xerox and Samsung. We offer only original (OEM) products, at very low prices. We invite you to shop around for your cartridges; we are confident we're offering the best deal.

Why only OEM cartridges?

PG TECH was founded in 2002 by Pierre Gaulin. Trained in printer repair and maintenance (and in cinema!), he was aware if the high demand for expertise in this field. He founded the business with the premise that repairing also means to reduce and to recycle, in a world of increasing consumption where everything is disposable. People purchase discounted printers that do not meet their needs, and they throw them away when they find the cartridges to be too expensive on the longer run.

Since then, Pierre has repaired 18,000 printers, mostly at the workshop, and others at your offices and homes. In that way, he built up his expertise on experience.

Today, it's in this same quest for sustainability that we are stepping into the world of online commerce. Original (OEM) cartridges are the ones we naturally want to offer you. They are solid, nearly unfailing, they offer a better yield, and they are the only ones that provide an image quality that reflects your expectations. Furthermore, since we specialize in repair, we do know quite a bit about compatible cartridges, and we have no reason to recommend them. Have we convinced you yet?

In order to shed light upon the products we are offering you online, we thought we'd share with you the manufacturing process behind these cartridges, along with other good-to-know secrets.

Toner manufacturing

There are two different methods of fabrication: polymerization and pulverization.

A_ Polymerized toner particles (OEM toner) B_ Pulverized toner particles (refurbished / recycled toner)

Polymerization

This is the method used by the printer fabricants to manufacture the original toner cartridges. Pigment particles are set into motion with additives :

► Black Charcoal (you guessed it: this is the pigment for Black)

► Pigment Yellow 180, a benzimidazole compound

► Pigment Red 122, a quinacridone compound, used to produce the Magenta color

► Pigment Blue 15:30, Copper phthalocyanine that produces Cyan

+ Silica prevents particles from agglomerating, facilitating the homogeneous spreading of toner over the paper

+ Charge Control Agents (small amounts of iron, chromium or zinc) carry the static charge, which is created when the toner hits the blade as it's propelled to the drum. This electro-static charge is essential; it takes the toner to the paper.

Through a chemical reaction, these different types of particles tighten together into agglomerations of equal sizes and nearly identical composition: toner particles. These particles of ideal size produce precise images and lines. Also, the wax coating, which gives the image a silky texture, also protects it from folding and toner streaking. It also helps preventing paper jam. One key element in the printing process is the fusion of the toner onto the paper. The fuser unit heats up to a given temperature to fix the print. What we would like to stress is that this temperature is set to suit OEM polymerized toner and cannot be changed. This temperature is often too low to properly fix pulverized (compatible) toner to the paper.

Pulverization

This is the method used to manufacture compatible / refurbished cartridges. Small pieces of polyester, a synthetic fiber made from charcoal, air, water and oil, are broken into smaller pieces. Silica, which is added to the mixture, is especially important for this method: since the material is broken instead of chemically produced, pulverized toner tends to agglomerate on the paper.

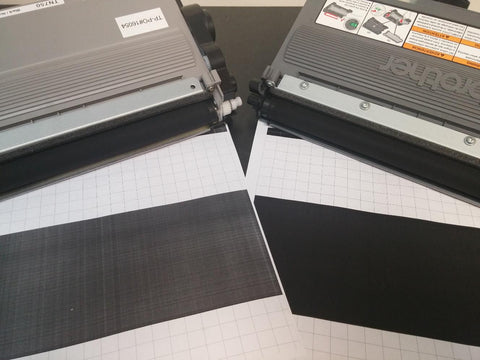

Pulverized toner particles are irregular and larger in sizes. They require a higher fusion temperature, one that is in fact higher than the one fuser produce. This underheated toner causes several of the issues we encounter through our repair services:

○ Toner not properly fixed to the paper (“dusty”)

○ Toner built-up that causes paper jam

○ Fuser unit warning out faster than normal

○ Poor image quality (“ghostly”, distorted, etc.)

Here is a test that compares the printing results of a compatible cartridge (left) with that of an OEM Brother cartridge (right).

Ink manufacturing

Whether it's black or of color, ink contents wax, lubricants, surfactants and siccatives. However, the most important ingredient is the pigment. For black ink, charcoal is used, just like for toner. A white pigment is used to adjust the color of other inks.

► Black Charcoal, used to produce Black ink

► ► ► Titanium dioxyde, to manufacture the white pigment, which is added in varying quantities to create the different colors

+ Varnish, a clear liquid, the base ingredient in the composition of ink

+ Resin, which binds together the ingredients and creates viscosity

video by The Printing Ink Company

Several inkjet printer models are equipped with more than four cartridges. In addition to the Black and the three colors, "mid-tone" colors are often included in the series: Light Cyan, Light Yellow, Grey. In printers designed for refined color precision, whole different colors are also added: Orange, Green, Blue. These tones and additional colors enable a wider range in the combination of colors. While, theoretically, all colors can be produced by the CMYK system (Black being a combination of all three colors), in the printing reality, this system is imperfect and certain nuances are difficult to produce, especially in the case of very pale tones.

As an example, here is the cartridge set for the Epson Stylus Pro 4900 Designer Edition.

Do your cartridges provide the expected yield?

The ink and toner cartridges meant for the most common printer models are often available in two formats. One has the "Standard Yield", around 150 to 350 pages for the inkjet system, and 1,500 to 2,000 pages for the laser system. The other format, "High Yield", offers approximately 400 to 2,000 pages for inkjet, and 5,000 to 12,000 pages for laser. This is a great difference and, just like for so many products on the market, one may save by purchasing larger formats.

One trick for the HP brand: The cartridges that have a code ending with A have a standard yield. Look out for codes ending with X; those have a high yield.

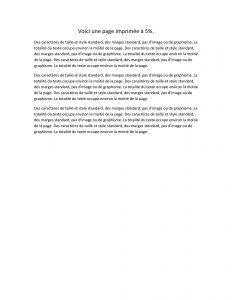

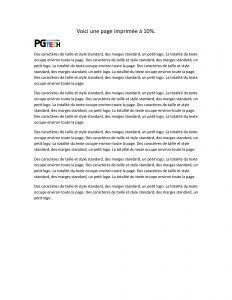

When talking about a cartridge's "yield", the reference is for pages with 5% coverage.

5%? One must imagine folding a letter-size sheet into 20 parts. The surface of the rectangle this creates represents the total surface covered in ink or toner that is considered standard for one printed page. Standard style and size characters, standard margins and no image or graphics. The whole text area uses about one half of the sheet. This is the reference used on the market to indicate cartridges' yield. It's the International Organization for Standardization (ISO) that conducts to determine a given cartridge's yield.

On the left, a page with 5% coverage; on the right, one with 10% coverage.

It's common they have a 10% or more page coverage. If one adds a logo, an image, a bold font or if the print itself is an image, then the cartridge with offer less prints.

Do you know the "cost per page" of your printer?

Well before restocking on cartridges, the hassle of supply expenses may be anticipated at the moment of the equipment purchase.

The cost per page is one of the most important aspects to consider when choosing a printer.

The technologies used in the different equipment, as well as the type of ink or toner they take, are factors that affect the cost per page.

One easy way to calculate the cost per page is to divide the cost of a cartridge by its yield.

For example, a comparison between a standard yield toner cartridge, with its high yield version:

The TN221C Cyan Toner Cartridge (Brother): $79.38; yield 1,400 pages → $0,06/page

The TN225 Cyan Toner Cartridge (Brother): $112.19; yield 2,200 pages → $0,05/page

*****

Inkjet vs. Toner

A quick cost per page comparison between the tricolor ink cartridge, and a set of the three colors of toner cartridge:

C9352AC Tricolor Ink Cartridge n° 22 (HP): $38.46; yield 165 pages → $0,23/page

CF341A Cyan, Magenta, & Yellow Toner cartridges 126A (HP): $212.81; yield 1,000 pages/cartridge (3,000 pages/set) → $0,07/page

Conclusion: In this specific case, the inkjet print costs $0.16 more per page than the laser print.

Of course, this difference will vary between cartridge models, and other factors can contribute, to a lesser extent, to the cost per page. However, the inkjet system does generally have a higher cost per page than the laser system, and this is true whether one prints color or monochrome. Inkjet printers still offer a higher color precision; it's the system used in the photography and design industries.

Come back often! We have more tips to share with you.